EcoPro Innovation

Company status

-

Corporate name

EcoPro Innovation -

Establishment

July 2005 -

CEO

Kim Yoon tae -

Employee status

258 people As of march 2025 -

Sales

KRW 127.0 billion 2024 Annual Report -

Capital

KRW 560.4 billion 2024 Annual Report

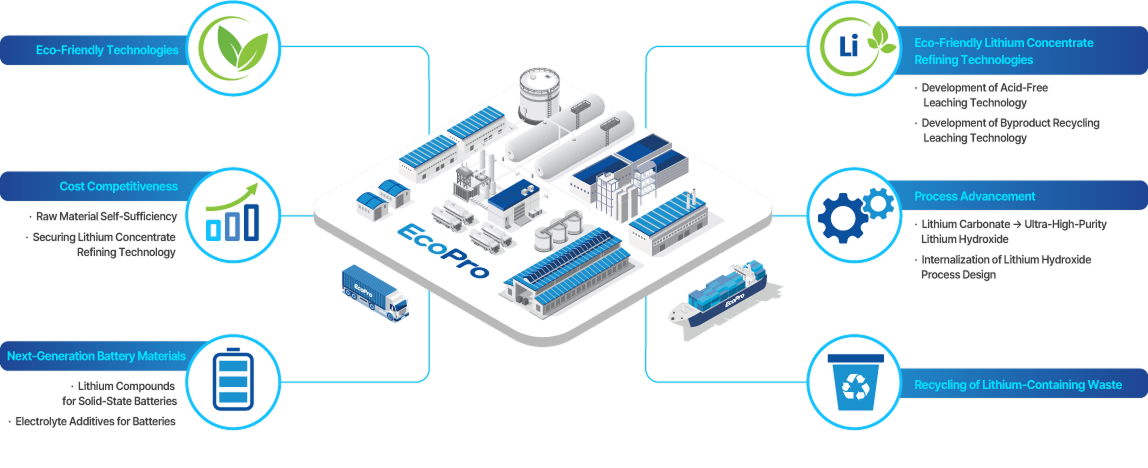

Main Business Area

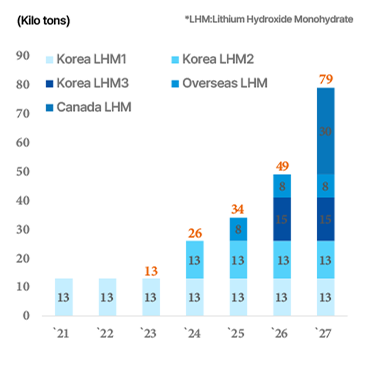

Lithium Hydroxide

Manufacturing of lithium hydroxide for use in batteries from salt lakes, ore, and recycled materials

Production of various lithium products

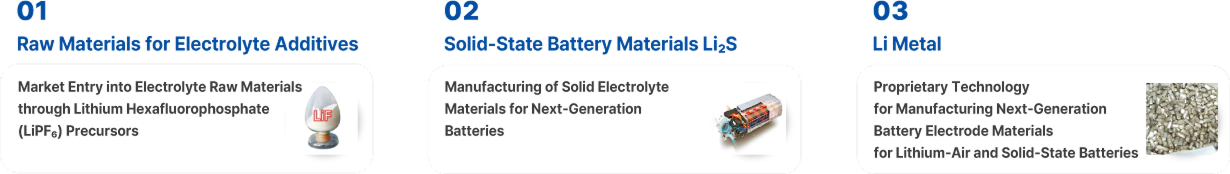

Securing next-generation lithium-related technologies